Innovation

Our advanced condition monitoring technologies

Empower your turbines with seamless blade monitoring

Take full control of blade performance with ease. Our advanced blade condition monitoring technology ensures that all blade issues are efficiently detected and managed, keeping your turbines running at peak efficiency.

Designed for retrofittability and simplicity, our solution operates independently of OEMs and SCADA systems, with the added assurance of global certification. Experience effortless, reliable monitoring from a single trusted source.

Gain control: Streamlined decision-making for wind turbine operators

When critical issues arise, operators need clear, actionable insights – without being overwhelmed by data. EOLOGIX-PING consolidates essential information into a single, intuitive dashboard, providing a comprehensive overview for fast, informed decisions.

Whether managing a single turbine or an entire wind farm, EOLOGIX-PING simplifies data management, enabling efficient maintenance planning and maximizing turbine uptime and performance.

Why continuous condition monitoring matters

Wind turbines operate in ever-changing environmental conditions, each posing unique risks to performance. Early detection of issues such as malfunctions, damage, or downtime is essential to minimizing revenue loss, controlling maintenance costs, and maintaining operational efficiency.

Continuous monitoring ensures proactive intervention, protecting your investment and optimizing turbine performance over the long term.

Our holistic blade monitoring technologies

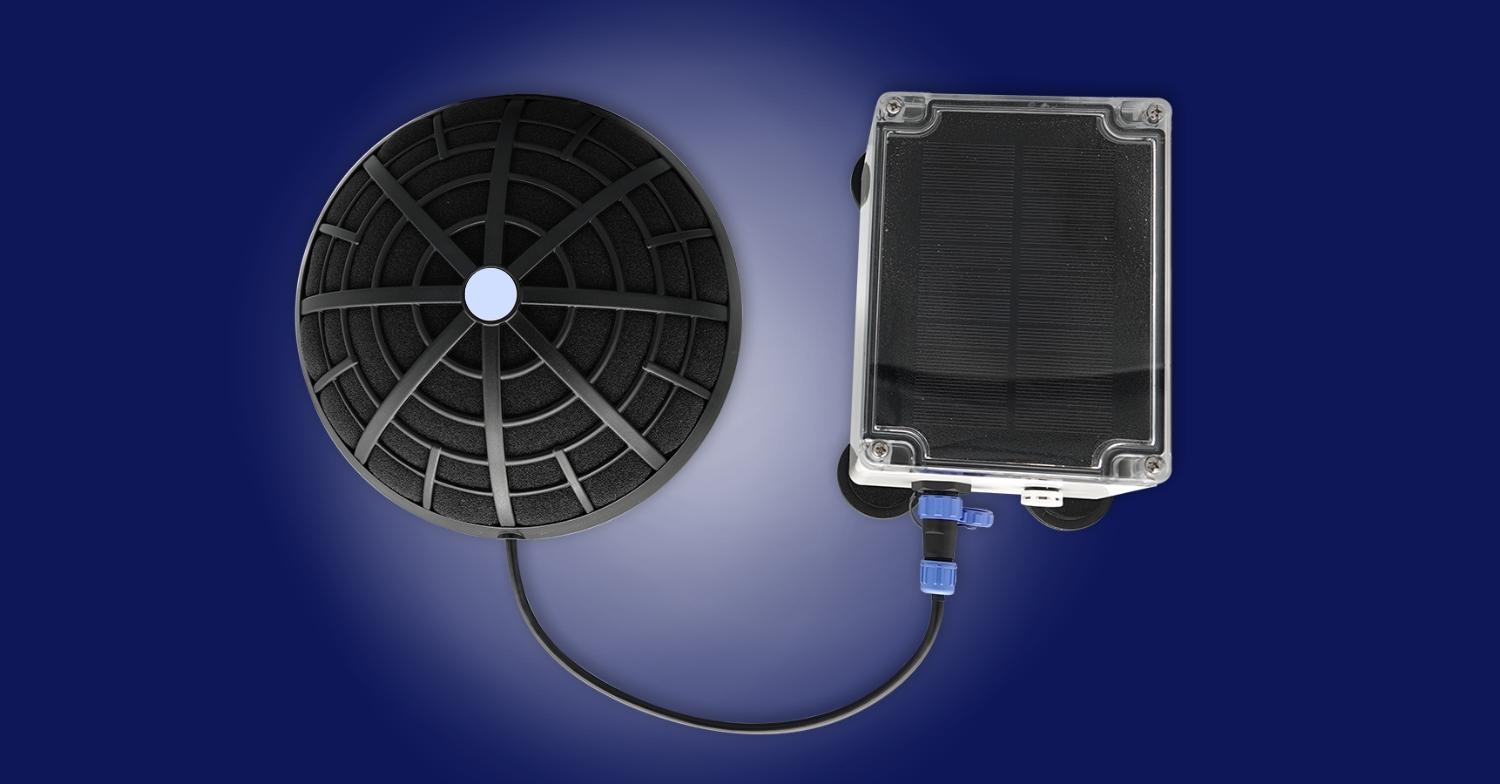

ON-TOWER (OT)

ON-TOWER blade health monitoring device for enhanced wind turbine performance and longevity consists of an Intelligent Listening Sensor (ILS) and a Power and Communication module (PCM). It is easily mounted with magnets or adhesive at the base of the tower.

Why choose our ON-TOWER monitoring?

- Peace of mind

- Swift notifications

- Quick installation in under 10 minutes for steel towers

This plug-and-play device is best installed on the windward side, facing the sun

Overview

Used technology

- Acoustic sensors (blade damage and icing)

- Magnetic field detector (lightning events)

IN-BLADE (IB)

The IN-BLADE device for internal root zone damage detection features an IN-BLADE Unit (IBU), powered by a Kinetic Power Supply (KPS). Alternatively, the IBU can be connected to the hub power supply (if available). Each blade requires one IBU and one KPS, mounted inside its root zone.

Why choose our IN-BLADE monitoring?

- Detect damage earlier

- See changes of damage level in the dashboard

- Self-powering and communicating (with use of KPS)

- Based on proven science of crack propagation and acoustic emission

Overview

Used technology

- Acoustic sensors

ON-BLADE (OB)

The ON-BLADE system for early icing detection and temperature measurement using capacitive sensing at multiple external blade surface points. It consists of mechanically flexible Wireless Blade Sensors (WBS), one base station per turbine and an antenna (two different options available).

Why choose our ON-BLADE monitoring?

- Only system on the market that measures directly on outer blade surface and determines actual ice thickness

- Can distinguish between rime ice and glaze ice

- Ice and temperature measurement at each sensor

- 5 levels of surface condition

- Temperature measurement +/- 0.25°C

- No data of the wind turbine necessary

- High redundancy of the system

Overview

Used technology

- Capacitive sensors

- Temperature sensors

- Inertial sensors

Trusted by these industry leaders

Our blade monitoring technology at a glance

The following overview gives you a good impression of our systems.

Common questions about our technology

Let's meet up

Webinars

NERC Icing Compliance - Practical Steps for Wind Operators

Every winter, wind operators face the same challenge: keeping people safe, protecting turbines, and maintaining production when ice hits. With new NERC EOP-12 ver. 3 requirements starting November 2025, what will this mean for daily operations - and how can you prepare, get the right data, and prove compliance during real icing events?

Fighting ice on wind turbines with precision: How smart blade heating can transform winter operations

This free, expert-led on-demand webinar show you how smarter blade heating enables targeted, efficient, and cost-effective icing control.

In-person events

February 17, 2026

EventWind Operations & Maintenance Australia 2026

Melbourne, Australia

Pullman Melbourne on the park

EOLOGIX-PING invites you to join industry leaders, experts, and innovators for two days of insights, practical solutions, and networking. Connect with us and help shape the future of wind energy.