Blade Operation Monitoring

Ice detection: Safeguarding performance in cold conditions

Our ice detection solutions provide peace of mind by seamlessly managing ice accumulation on your turbines. From early icing risk alerts to fully automated management during icing conditions, our products ensure your operations remain compliant with safety regulations. Keep your turbines running efficiently and optimize your time and resource planning with our advanced technology.

These companies use EOLOGIX-PING’s ice detection system

How our ice detection system helps you

Wind turbine operators aim to ensure optimal turbine performance under icing conditions while minimizing downtime. Our systems, equipped with capacitive and temperature sensors, continuously monitor icing events and temperature, optimizing turbine operation in wind and cold climate regions.

Keep turbines running

Our ON-BLADE ice detection systems, featuring Wireless Blade Sensor (WBS), ensure more uptime by accurately distinguishing between rime and glaze ice. This capability not only keeps your turbine operational in challenging conditions but also reduces the risk of ice throw hazards.

Stay informed with accurate ice accumulation detection

Our system not only meets stringent safety regulations but also promptly alerts you to the presence of ice. Equipped with Wireless Blade Sensors (WBS), it accurately measures ice and temperature directly on the outer blade surface, discerning five distinct levels of surface condition (Level 1-5).

Certified and well proven

Our system is rigorously tested and endorsed by top certification bodies like TÜV Nord, DNV, and the Solar Impulse Foundation. It is trusted by major wind turbine manufacturers and utilized by wind turbine operators worldwide, ensuring reliability and performance you can count on.

Fully automated system

Our system offers automatic restart after ice accumulation, significantly reducing personnel costs and response times. Additionally, it operates independently, eliminating reliance on third-party data and minimizing the need for physical inspections during harsh winter conditions, ensuring uninterrupted operation.

No need for calibration or wiring

Our ON-BLADE solution requires no calibration or wiring, ensuring rapid deployment and immediate readiness for operation. This streamlined setup saves time and eliminates complexities, allowing you to focus on maximizing turbine performance.

Our products at a glance

Blade risk

:LITE ICE

Monitoring the presence of light icing with acoustic sensors (ON-TOWER technology)

Blade risk

:STANDARD ICE

Blade-based system with stopping the turbine after ice accumulation (no rope access required)

Blade risk

:RESTART ICE

Blade-based system with stopping the turbine after ice accumulation and automatic restart after “ice-free” detection

Most Popular

What sets our ON-BLADE (OB) ice detection system apart?

The OB ice detection system (IDS) differs from other ice detection systems in several aspects

Maximize wind turbine uptime with reliable ice detection

Minimize revenue losses in the upcoming winter

Increased availability and safety of your wind turbines

Our advanced ice detection system distinguishes precisely between frost and glaze ice. It only stops the turbines in safety-critical situations. This significantly extends the operating time of your wind turbines and allows operators to maximize energy production and minimize unplanned downtime without compromising on safety.

Innovative technology approach

Our system is the world’s first solution for ice detection and temperature measurement directly on the surface of the rotor blade. It measures the ice level directly with the capacity sensors – other variables, such as vibrations, are not necessary for determination. Thanks to its design and flexibility, the sensor can be installed almost anywhere on the blade. This makes it particularly reliable and precise.

Autonomous system

Our autonomous ice detection system does not require SCADA data or third-party information to operate reliably. It is completely energy self-sufficient and ensures that the wind turbines can be operated efficiently even in remote areas without external energy sources

Only system with 100% availability

Our ON-BLADE Ice Detection Solution is designed for seamless integration with your turbine controller, requiring only a standard signal interface to operate.

By using multiple sensors on the blades, the system incorporates redundancy – if one sensor fails, the others continue to provide reliable ice detection. The system is not influenced by external factors like heavy icing or specific operating conditions (e.g., idling turbines, pitched blades, or heated blades). It can detect ice accumulation on the blades independently of these conditions, ensuring reliable performance.

This capability was proven in an independent study by Meteotest (2021), as part of the VGB Research Foundation’s project 401. The test, which compared four rotor icing detection systems installed on the same turbine, demonstrated that our solution achieved 100% availability during operation.

Choose your product

Our products have been designed to suit the respective levels. We therefore offer the right solution for different needs. (Note: All prices are valid for 2025.)

:LITE ICE

Monitoring the presence of light icing with acoustic sensors (OT technology)

- Uses the acoustic ON-TOWER technology

- Is equipped with PCM as receiving unit

- Is mounted on the base of the turbine

- Detects the presence of light icing

Cost Overview

Standard

:LITE ICE

•

Detects the presence of light icing

•

Mounted with magnets or adhesive on the base of the tower

Package includes

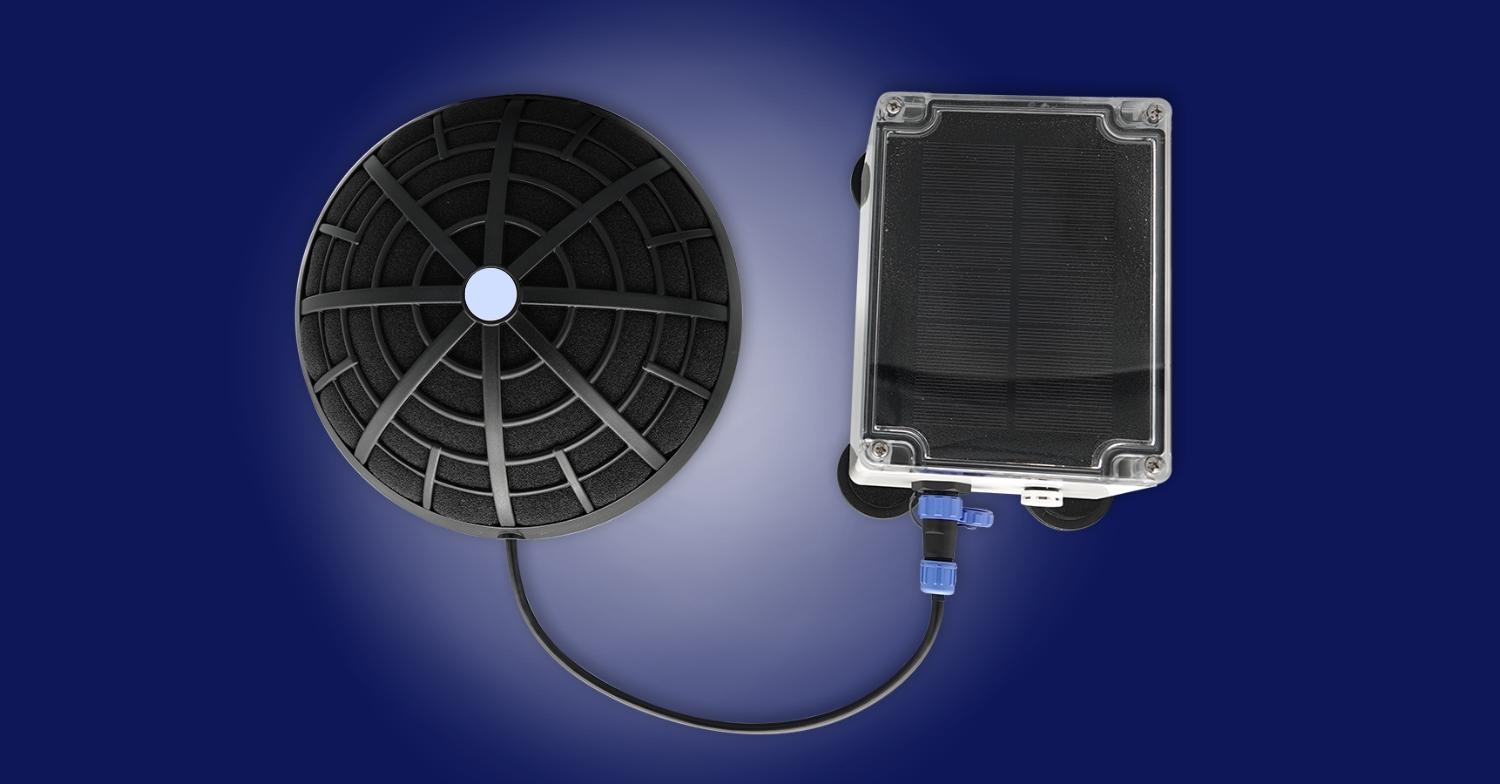

This package contains the Intelligent Listening Sensor (ILS), Power- and Communication Module (PCM) and the Interconnecting Cable (IC).

:LITE ICE starting at

per wind turbine per year

Ice detection common questions

Any questions?

Reach out to us for tailored advice on your specific needs, to learn more about our technology, or to schedule a personal consultation. Our dedicated team is ready to assist you every step of the way.