9 min to read

Effective blade heating for wind turbines - an overview

Published: December 12, 2023

Updated: July 10, 2025

Table of Content

Wind turbines are exposed to various environmental influences all over the year – with sometimes considerable effects on performance, yield and safety. Icing also plays a major role here. Innovative blade heating systems therefore offer various approaches to solving the icing problem and protecting the environment and your service team. In this article, we will give you an insightful overview.

Rotor blade heating solutions

There are two main solutions for rotor blade heating established by wind turbine manufacturers (OEMs) on the market:

- hot air heating inside the rotor blade

- electro-thermal heating elements laminated in the blade surface

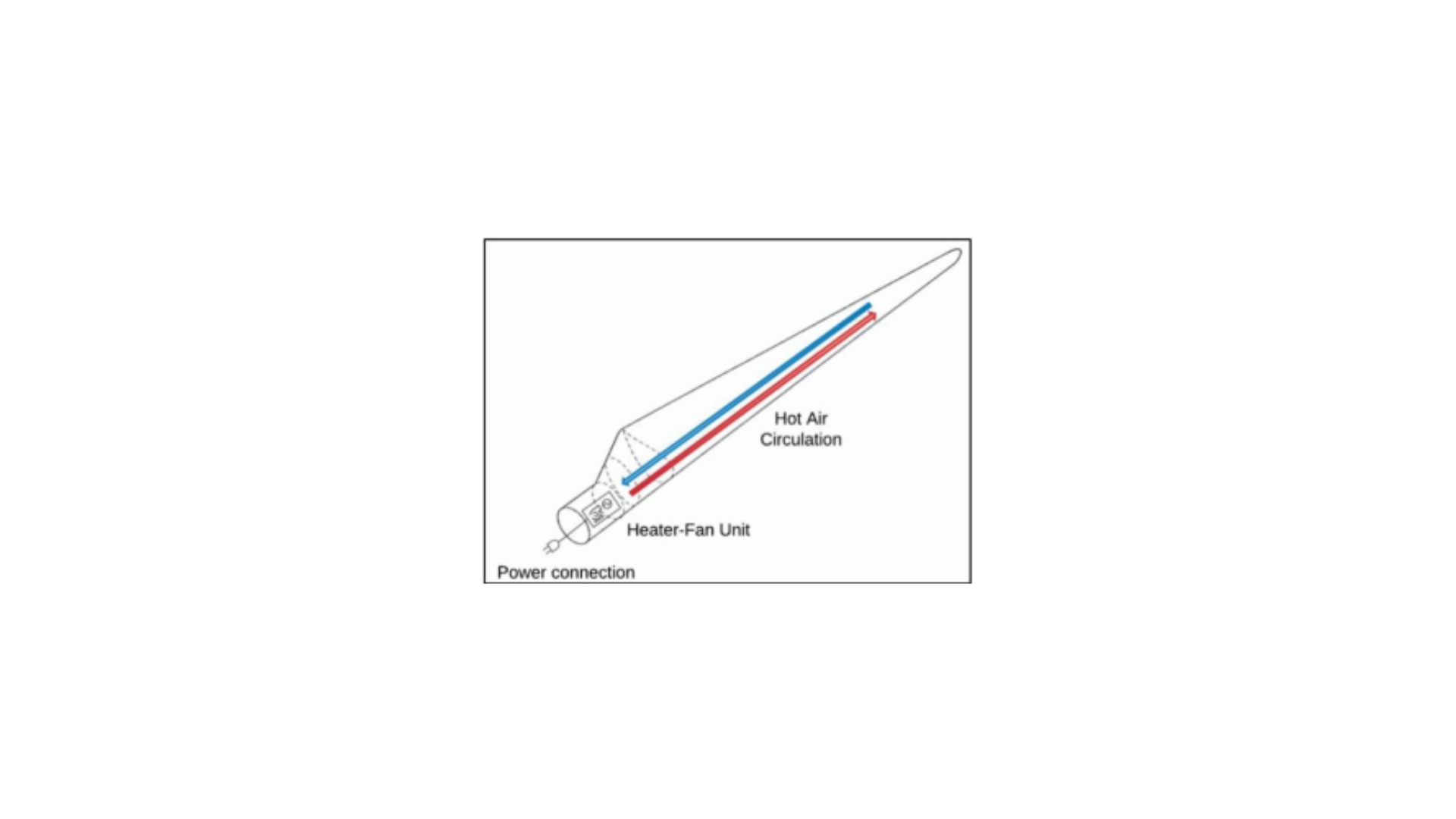

Hot air inside the blade

With this method, a heater-fan unit creates an air flow in specific channels in the rotor blade. The hot air passes by the leading edge, warms up the shell material to the blade surface above 0 °C and allows to thaw the ice layer. The same device can also be used as a de-icing system.

- enables continuous operation

- prevents ice accumulation

Hot air heating (Charles Godreau 2022**)

Charles Godreau 2022

Electro-thermal heating elements

This method uses electro-thermal heating elements, which are embedded inside the rotor blade or laminated in the blade surface layer. This technology not only allows continuous operation, but also effectively prevents ice accumulation.

Electro-thermal heating (Charles Godreau 2022**)

Copyright: Charles Godreau 2022

The operating strategy of the rotor blade heating plays a key role in both systems. This should be taken into account to optimize efficiency, reduce heating costs and prevent overheating and damages due to overheating.

Download blade heating whitepaper

Would you like to find out more about efficient blade heating? Our comprehensive whitepaper gives you a useful insight into this topic.

Wind turbine rotor blade heating solutions from OEMS

Different OEMs* have developed different approaches to rotor blade heating to meet specific requirements.

Enercon

Enercon’s technology combines an ice detection system with hot air circulation inside the rotor blades for efficient de-icing. The duration of the de-icing process depends on the ambient temperature and wind speed. As soon as the process is complete, the turbine can be restarted with ice-free rotor blades. At sites with minimal icing risk, the system allows de-icing to be carried out while the turbine remains running.

Key design features**

- Energy consumption between 46kW and 225kW

- first prototype in 1996

- more than 3000 blade heating systems installed worldwide

Nordex

The Nordex system consists of an ice sensor and electrothermal heating mats (underneath the blade surface) at the leading edge of each rotor blade. The sensors continuously monitor ambient conditions and report the status to the wind turbine’s operational management system.

- If icing conditions appear, the system offers two different options:

- stopping the turbine to protect structural integrity or

- removing the accumulated ice via the Nordex Advanced Anti-Icing system (AAIS)

Siemens Gamesa***

Siemens Gamesa relies on a blade heating system** with an ice detection system, blade heating elements (integrated into the blade surface at the OEM) and a system to control the de-icing strategy.

Siemens Wind Power De-icing Strategy

- ice detected (through power curve deterioration, ice detection sensor or low toque ice detector)

- the turbine is stopped in static or idle mode (0-2 Rotor rpm)

- the nacelle yaws so the rotor is in “back-wind” or in “safe angel of rotor disc vs. nearby objects”

- De-icing is activated on all three blades

- After x min, the nacelle yaws back into the wind

- Once the turbine is producing again, de-icing is deactivated

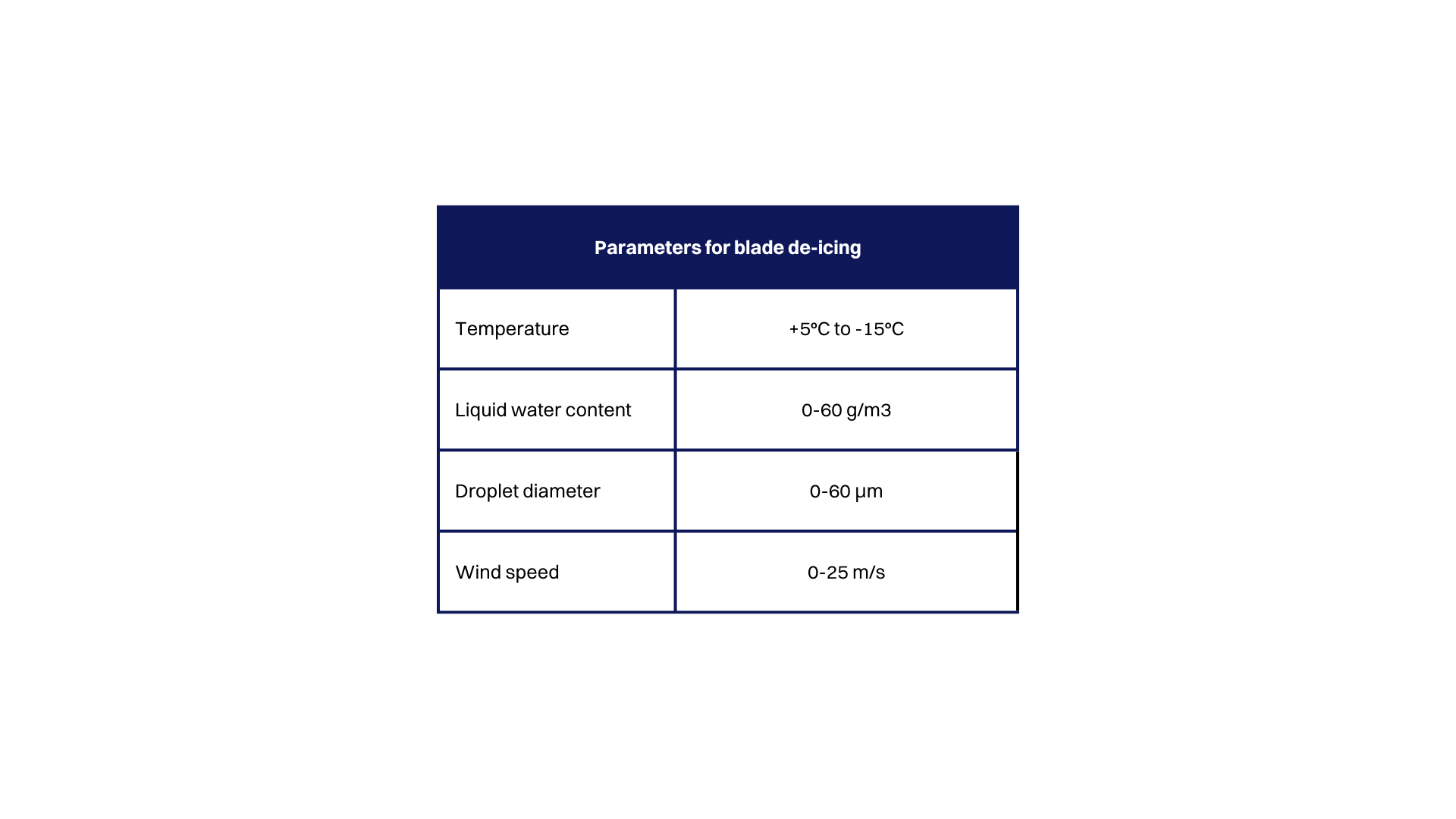

Parameters for blade de-icing (Charles Godreau**)

Copyright: Charles Godreau

Vestas

Vestas offers various solutions for sites with cold climates. The Vestas Anti-Icing System™ combines several independent heating elements and levels, which – according to Vestas – enable anti-icing measures tailored to the respective icing event.

- Individual powering of heating elements to secure equal power distribution where it is needed

- Compatible with Vestas Ice Control (optional feature of the Vestas SCADA system that orchestrates the standard yawing and pausing functionalities of the turbine with different ice mitigation actions)

Vestas Anti-Icing SystemTM

Copyright: Vestas

Retrofittable heating solutions for wind turbine rotor blades

In addition to manufacturer solutions, there are various providers who offer retrofittable solutions. You can find more details in our white paper on blade heating.

Source (if there is no link in the text):

- **Charles Godreau (2022): Tackling Icing on Wind Turbines with Ice Protection Systems, Current State -of-the-Art and Future Research, NERGICA, IGW Wind Industry Stakeholder Meeting

- *** Will heat be the winner in de-icing turbine blades? | Reuters Events | Renewables. (o. D.). Abgerufen am 20. Oktober 2022, von https://www.reutersevents.com/renewables/wind-energy-update/will-heat-be-winner-de-icing-turbine-blades & Siemens Gamesa. (o. D.). Onshore technological solutions. Abgerufen am 17. September 2022, von https://www.siemensgamesa.com/en-int/-/media/siemensgamesa/downloads/en/products-and-services/onshore/brochures/siemens-gamesa-onshore-tech-solutions-en.pdf

Share this blog post

Get your blade heating whitepaper

In our comprehensive white paper, you can find out about the benefits of intelligent blade heating.

Subscribe to our newsletter

Stay informed with the latest industry news, fascinating insights, and updates from EOLOGIX-PING delivered straight to your inbox.

PS.: We promise no spam.